Fri, Nov 15, 2024

[Archive]

Volume 15, Issue 2 (June 2018)

IJMSE 2018, 15(2): 76-87 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Farzan F, Shahverdi H R, Malek Ghaeni F. Effect of Wet and Dry Conditions on Wear Behavior of Amorphous Coating of Fe-Cr-Mo-Nb-C-B. IJMSE 2018; 15 (2) :76-87

URL: http://ijmse.iust.ac.ir/article-1-1061-en.html

URL: http://ijmse.iust.ac.ir/article-1-1061-en.html

Abstract: (19183 Views)

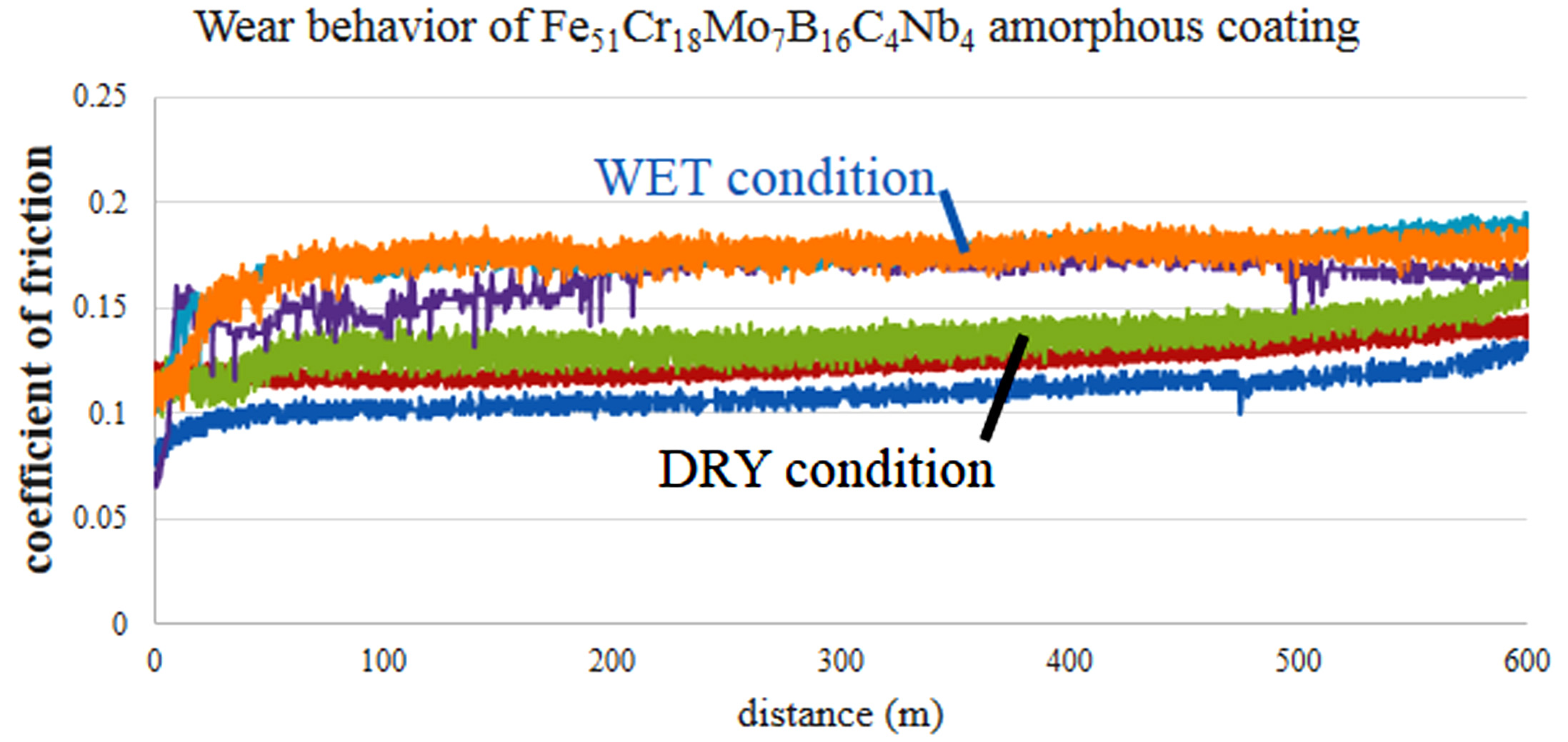

Recently, wear resistant properties of metallic glasses has attracted a lot of interest. Because the surface of metallic glasses are prone to phase transformation, finding the effects of test condition on structure and wear behavior of metallic glasses is important. In this research, by using an automated electrospark deposition (ESD), a layer of Fe51Cr18Mo7B16C4Nb4 was deposited on AISI 316l stainless steel. Metallographic, scanning electron microscope (SEM) and Energy-dispersive X-ray spectroscopy (EDS) analyses of the coating were conducted for measuring the thickness and analyzing composition of the coating. X-ray diffraction (XRD), Transmission electron microscopy (TEM) and selected area electron diffraction (SAED) investigations showed that the structure of the coating was amorphous. Ball on disc wear tests were conducted in dry and wet conditions and Ringer’s solution was chosen as the wetting agent. The wear test results showed that the coefficient of friction in dry condition was lower than the wet condition and wear modes were fatigue and corrosive wear in dry and wet conditions respectively. SEM and EDS analyses showed different features and elemental inhomogeneity on the surface of the dry wear track, which were not detectable in wet wear track. In addition, activation of diffusion process and formation of carbides and borides were observed on the wear track in dry condition.

Type of Study: Research Paper |

Subject:

Surfe coating and corrosion

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |