Sun, Nov 10, 2024

[Archive]

Volume 16, Issue 2 (June 2019)

IJMSE 2019, 16(2): 55-67 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

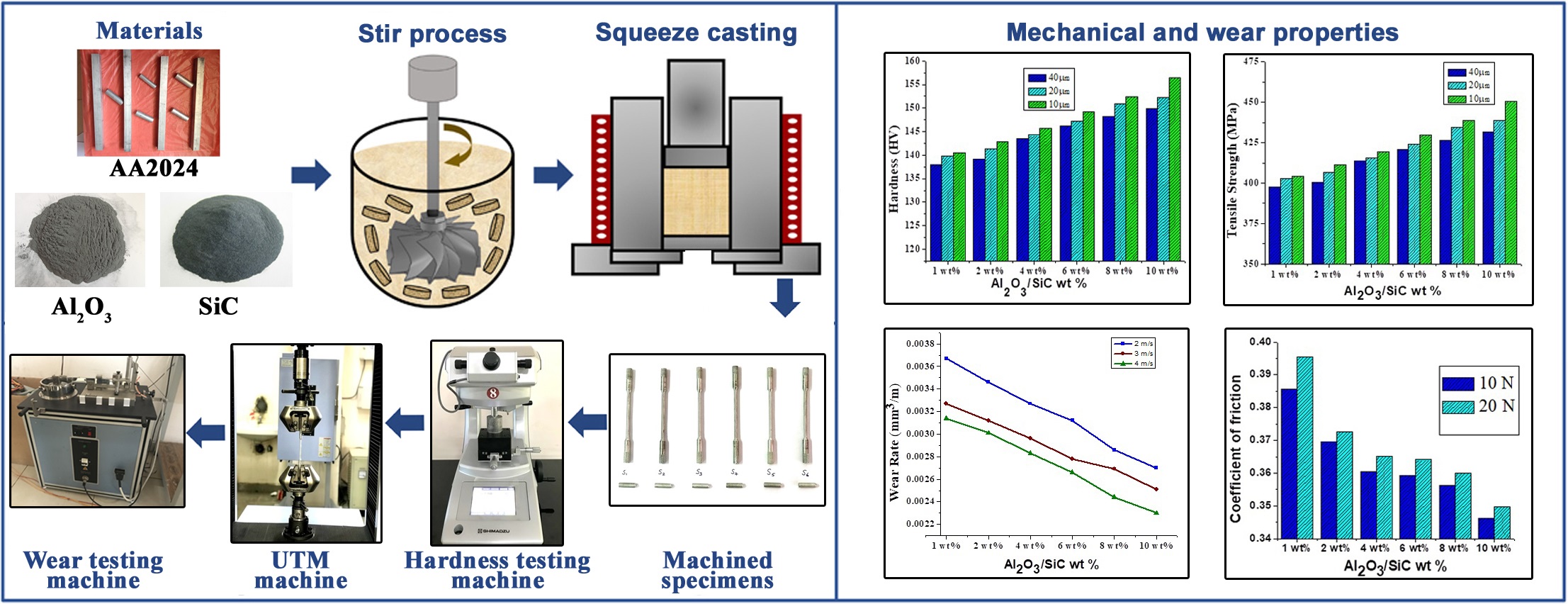

Senthil Kumar M, Managalaraja R V, Senthil Kumar K, Natrayan L. Processing and Characterization of AA2024/Al2O3/SiC Reinforces Hybrid Composites Using Squeeze Casting Technique. IJMSE 2019; 16 (2) :55-67

URL: http://ijmse.iust.ac.ir/article-1-1160-en.html

URL: http://ijmse.iust.ac.ir/article-1-1160-en.html

Abstract: (19827 Views)

The present requirement of automobile industry is seeking lightweight material that satisfices the technical and technological requirements with better mechanical and tribological characteristics. Aluminium matrix composite ( AMC ) materials meet the requirements of the modern demands. AMCs are used in automotive applications as engine cylinders, pistons, disc and drum brakes. This paper investigates the effect of particle size and wt% of Al2O3/SiC reinforcement on mechanical and tribological properties of hybrid metal matrix composites (HMMCs). AA2024 aluminium alloy is reinforced with Al2O3/SiC different particle sizes (10, 20 and 40 µm) and weight fractions (upto 10 wt %) were fabricated by using squeeze casting technique. HMMCs were characterized for its properties such asX-ray diffraction (XRD), density, scanning electron microscope ( SEM ), hardness, tensile strength, wear and coefficient of friction. AA2024/5wt%Al2O3/5wt%SiC with 10 μm reinforced particle size showed maximum hardness and tensile strength 156.4 HV and 531.43 MPa and decrease in wear rate was observed from from 0.00307 to 0.00221 for 10N. Hybrid composites showed improved mechanical and wear resistance suitable for engine cylinder liner applications.

Type of Study: Research Paper |

Subject:

Ceramics

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |