BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

URL: http://ijmse.iust.ac.ir/article-1-1645-en.html

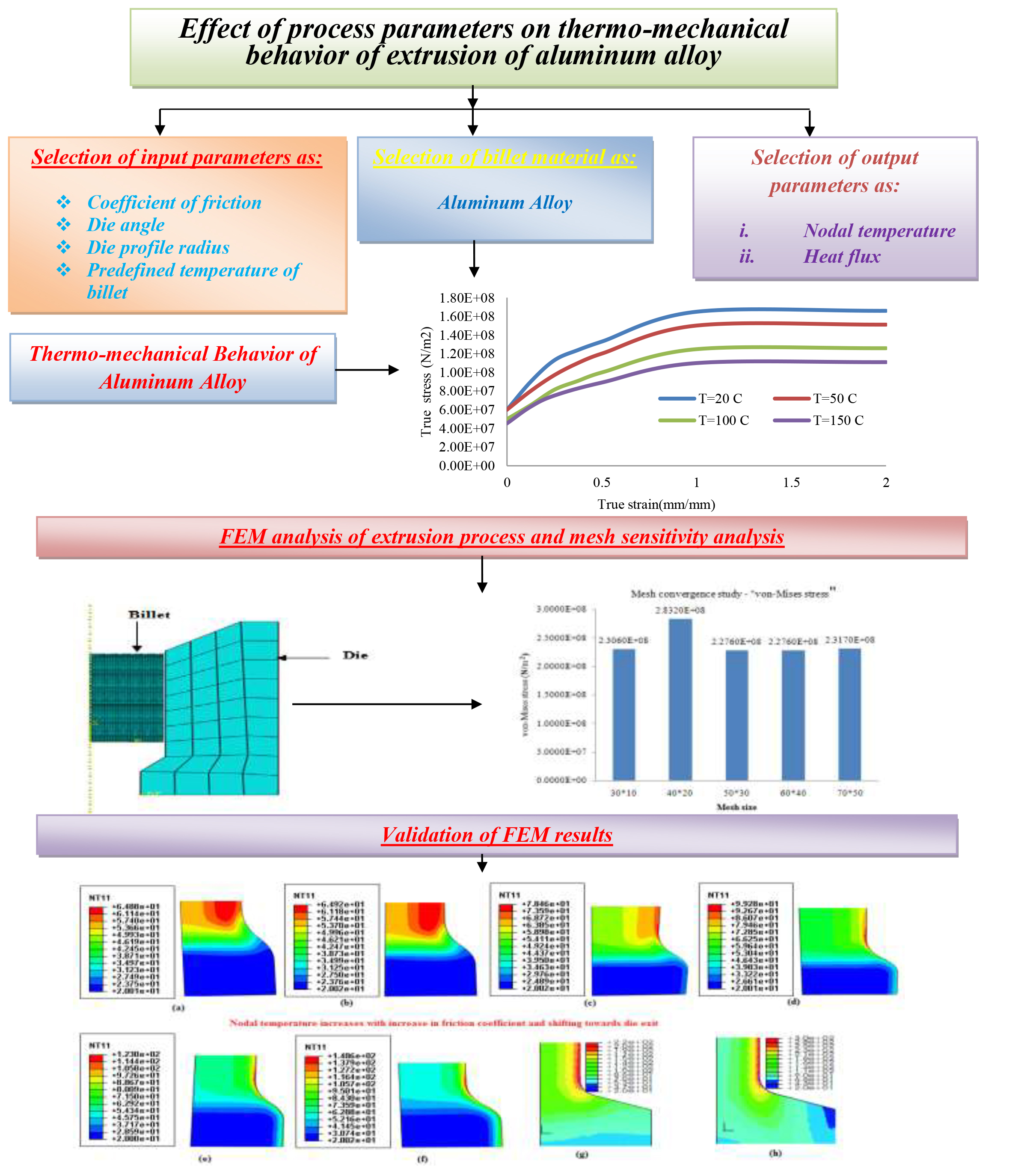

Finite element analysis has been carried out to investigate the effect of various parameters on axisymmetric hot extrusion process using aluminum alloy. The objective of the present work is to investigate the effect of friction coefficient, die angle, die-profile radius and predefined temperature of workpiece through FEM simulation of extrusion process. Nodal temperature distribution, heat flux, peak temperature at nodes and peak flux induced are identified as the output variables to assess the thermo-mechanical deformation behavior of aluminum alloy. Mesh sensitivity analysis is performed for the evaluation of mesh convergence as well as depicts the accuracy of present FEM model. Higher will be the coefficient of friction between interacting surfaces of die-billet assembly, more will be the increment in nodal temperature in billet. Higher will be the coefficient of friction, higher will be the generation of heat flux within billet, as this is achieved for highest coefficient of friction. Peak nodal temperature diminishes with increase in die profile radius nearly by 17 %.Maximum heat flux diminishes non-linearly by 30% with increase in die profile radius. Maximum nodal temperature increases nearly linearly by 14% with increment in predefined temperature of billet. Maximum heat flux decreases non-linearly by 5 % with increment in the initial temperature of workpiece. Validation of present numerical model is established on the basis of deformation behavior in terms of evolution of nodal temperature distribution upon comparison with previous studies available in literature.

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |